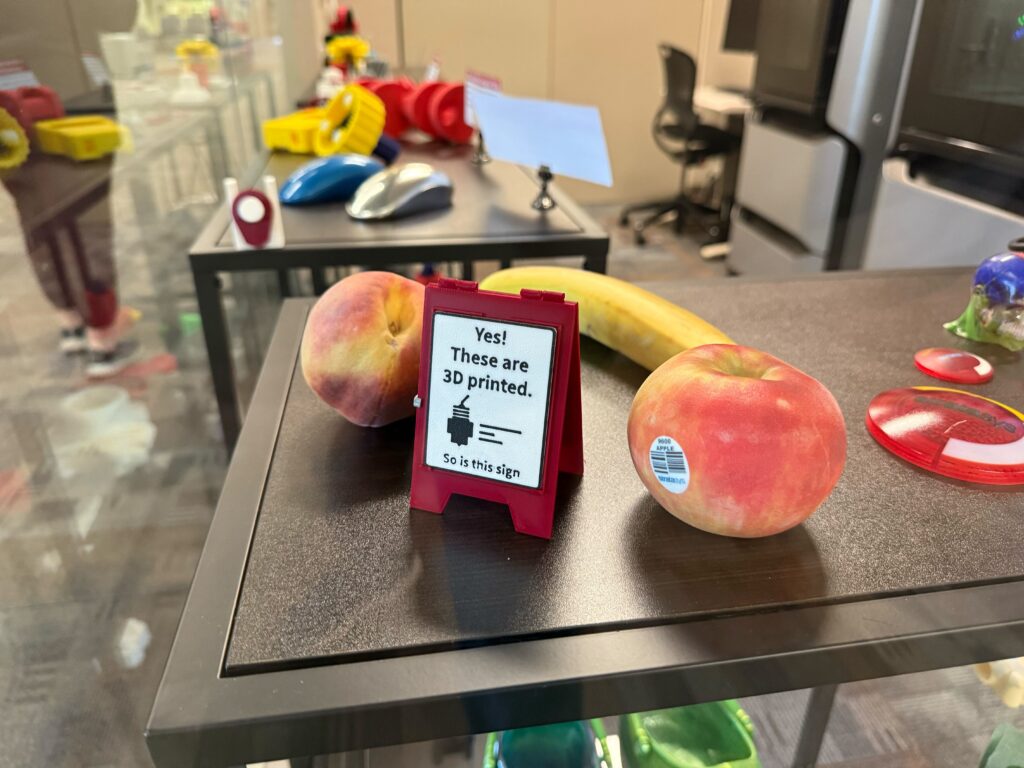

3D printing has only become a widely known concept in recent years. Since it has entered the zeitgeist, it has found many fans and contributors. The ability to make products in one’s own home with just a spool of plastic and a relatively small machine is a very tempting prospect.

This accessibility makes 3D printing very exciting. Yet, many hesitate due to its perceived complexity. The individual processes aren’t beyond the capabilities of most people, but few have experience with the specific steps required.

3D printing is not something that most individuals have experience with; its novelty makes it hard to know where to start. Fortunately, Sinclair Community College has a lab where students can begin gaining experience.

The 3D Printing Lab at Sinclair makes getting started with additive manufacturing easy through hands-on guidance.

“We’ll have students come in, and then they’ll talk to me, and then we’ll figure out how to print what they want to print. So I would prefer that they come to me with a model that they want to print, and then we’ll talk about how we can print it, what would be the best way to do it,” McKenzie Chumley, a lab tech for Mechanical Engineering, said.

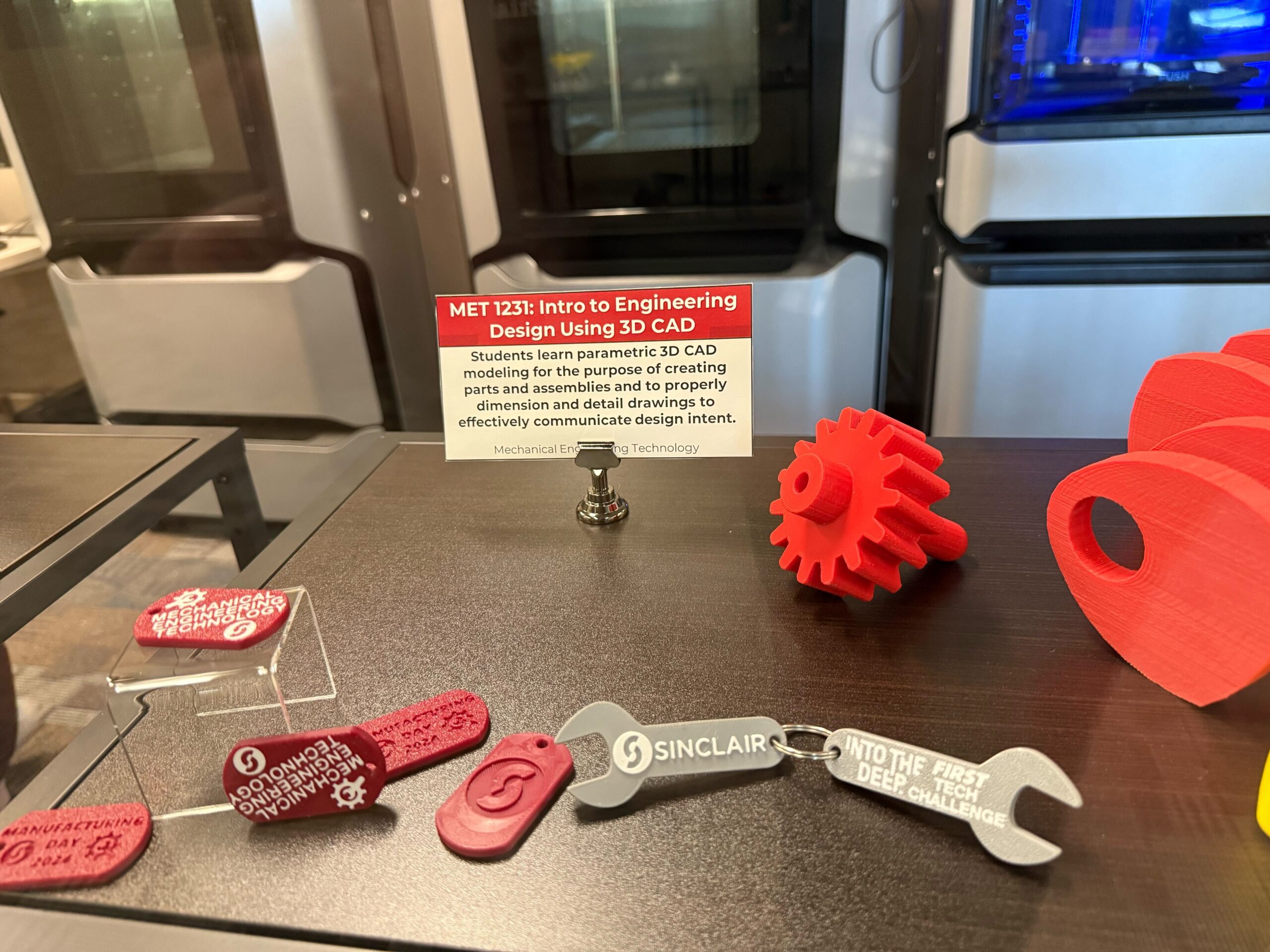

Although 3D printing is a program on its own, it is not separate from other programs here at Sinclair, which enables students to acquire skills that are also useful in their classes.

3D printing is used in many different industries, and Chumley has utilized her skills in additive manufacturing to support various programs around Sinclair. The projects that come out of this lab can even assist with learning in class.

“I’ve worked with the culinary department and then I’m also working with the psychology department to make a neuron model. So they can have a neuron model that they can pull apart and have students put together so they can learn about neurons,” Chumley said.

An industry where 3D printing has taken off is manufacturing. Before the innovation of additive manufacturing, prototyping took much longer and was a whole process that required multiple steps and professionals. With 3D printing, however, this can all be done by one person.

“It allows us to rapidly prototype something and be able to have people show off things and just allow you to reiterate faster and faster. Be like, hey, this didn’t work. What can I do to change this? Instead of having to go through the whole production process of having to injection mold it,” Chumley said.

This massive change in the industry creates plenty of opportunities for students. 3D printing is a relatively new change and this means that there is still a demand for people skilled in it.

Not only that, but 3D printing is only getting bigger and more advanced. So, students who make their way into the manufacturing industry with these skills will be joining as their jobs become increasingly important, putting them in a great position.

“Since a lot of places are adopting 3D printing now, having already knowledge of how to model for 3D printing and maybe how to operate 3D printers, it opens up a lot of doors for them to either bring 3D printing into their workplace and streamline making parts and dimensioning things. It makes it a lot faster. A lot of places already have 3D printing, so you’re able to integrate into that workflow,” Chumley said.

Getting into this industry early could prepare students for the future of many industries. If any students are interested, they should reach out to the mechanical engineering department or see additional information here.

Andrew Barnes, Staff Writer/Intern

Latest Posts:

- More than a hobby: 3D Printing at Sinclair

- Listicle with The Clarion: Five Books to Read This Summer

- Double the Expertise: Siblings Advancing Education at Sinclair Community College

- Correction: Dayton NATO Story in April Print Edition Amended

- Inside the Most Competitive NBA Playoffs in Years